Board Feet Calculator

Is this tool helpful?

How to use the tool

- Thickness (in) – type the true thickness. Example 1: 2 in; Example 2: 0.75 in.

- Width (in) – enter the actual width. Example 1: 10 in; Example 2: 5.5 in.

- Length – key in the board length, then pick the correct unit.

• Example 1: 6 ft (Feet selected).

• Example 2: 30 in (Inches selected). - Pieces – number of identical boards; default is 1.

• Example 1: 2; Example 2: 12. - Waste % – add extra to cover defects or cuts.

• Example 1: 8 %; Example 2: 12 %. - Press Calculate; three results appear: board feet per piece, total board feet, and waste-adjusted total.

Formulas used

When length is in feet:

$$ \text{Board Feet} = rac{\text{Thickness (in)} \times \text{Width (in)} \times \text{Length (ft)}}{12} $$When length is in inches:

$$ \text{Board Feet} = rac{\text{Thickness (in)} \times \text{Width (in)} \times \text{Length (in)}}{144} $$Example calculations

- Example 1 – 2 in × 10 in × 6 ft, 2 pieces, 8 % waste • Per piece: 2 × 10 × 6 ÷ 12 = 10 BF • Total: 10 × 2 = 20 BF • Adjusted: 20 × 1.08 = 21.6 BF

- Example 2 – 0.75 in × 5.5 in × 30 in, 12 pieces, 12 % waste • Per piece: 0.75 × 5.5 × 30 ÷ 144 = 0.86 BF • Total: 0.86 × 12 = 10.31 BF • Adjusted: 10.31 × 1.12 = 11.55 BF

Quick-Facts

- 1 board foot = 144 cu in = 0.00236 m³ (Wood Handbook, USDA 2021).

- Construction lumber is graded “KD-19” when kiln-dried to ≤ 19 % moisture (IBC §2303.1.9, 2021).

- Typical framing waste allowance: 10 % (Fine Homebuilding, 2019).

- Average U.S. hardwood price: $3.50 per board foot in 2023 (Hardwood Market Report, 2024).

FAQ

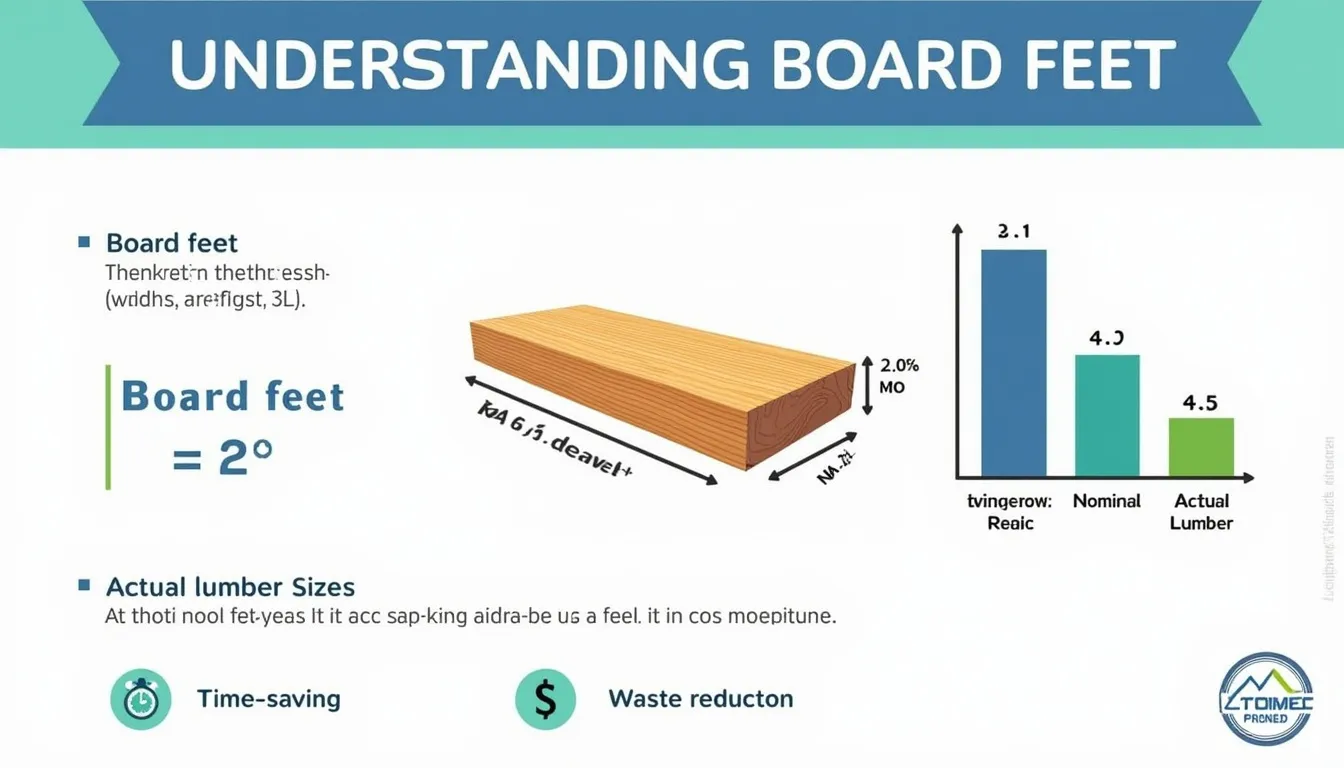

Why use actual instead of nominal dimensions?

Nominal sizes like “2 × 4” mask finish losses; actual 1.5 × 3.5 in numbers give volume accuracy and cost control (Wood Handbook, USDA 2021).

How does length unit affect the math?

Selecting “Feet” divides by 12, while “Inches” divides by 144, ensuring the result always equals cubic inches ÷ 144.

What waste percentage suits fine furniture?

Hardwoods with figure or knots need 15-20 % waste to allow matching and defect cutting (Popular Woodworking, 2020).

How do I price an order once I know board feet?

Multiply total board feet by the supplier’s rate; 150 BF at $3.50 /BF costs $525 (Hardwood Market Report, 2024).

Can I convert board feet to cubic metres?

Yes; multiply board feet by 0.00236 to get cubic metres (Wood Handbook, USDA 2021).

Does wood species change the calculation?

Volume math stays the same; species affects density, weight and cost only (Forest Products Lab, 2021).

What is the typical density per board foot?

Air-dried red oak averages 2.9 lb/BF, while pine averages 2 lb/BF (USDA Forest Service, 2010).

Is board foot used outside North America?

Metric markets price lumber by cubic metre; you can still convert board feet for quick U.S. comparisons (CSA O141, 2020).

Important Disclaimer

The calculations, results, and content provided by our tools are not guaranteed to be accurate, complete, or reliable. Users are responsible for verifying and interpreting the results. Our content and tools may contain errors, biases, or inconsistencies. Do not enter personal data, sensitive information, or personally identifiable information in our web forms or tools. Such data entry violates our terms of service and may result in unauthorized disclosure to third parties. We reserve the right to save inputs and outputs from our tools for the purposes of error debugging, bias identification, and performance improvement. External companies providing AI models used in our tools may also save and process data in accordance with their own policies. By using our tools, you consent to this data collection and processing. We reserve the right to limit the usage of our tools based on current usability factors.