Is this tool helpful?

How to Use the Valve Flow Coefficient Converter

Our valve flow coefficient converter provides a straightforward way to convert between Kv (metric) and Cv (imperial) values. Here’s how to use it effectively:

- First, select your desired conversion direction from the dropdown menu: “Kv to Cv” or “Cv to Kv”

- Enter the value you wish to convert in the “Input Value” field

- Choose the number of decimal places for your result (default is 2)

- Click the “Convert” button to see your result

For example, if you need to convert a Kv value of 25.5 m³/h to Cv, simply:

- Select “Kv to Cv”

- Enter “25.5”

- Keep the default 2 decimal places

- The result will show: 25.5 m³/h = 29.48 GPM

Understanding Valve Flow Coefficients

Valve flow coefficients are essential measurements in fluid system design and engineering. They represent the flow capacity of valves under specific conditions, with Kv and Cv being the two primary standards used worldwide.

The Metric Kv Coefficient

Kv (metric flow coefficient) represents the flow rate of water in cubic meters per hour (m³/h) through a valve with a pressure drop of 1 bar at a specific reference temperature.

The Imperial Cv Coefficient

Cv (imperial flow coefficient) measures the flow rate of water in US gallons per minute (GPM) through a valve with a pressure drop of 1 psi at a reference temperature.

Mathematical Foundation

The conversion between Kv and Cv follows these fundamental equations:

$$Cv = Kv \times 1.156$$$$Kv = Cv \times 0.864$$Benefits of Using the Flow Coefficient Converter

- Instant, accurate conversions between metric and imperial flow coefficients

- Eliminates manual calculation errors

- Saves time in valve sizing and selection processes

- Facilitates international project collaboration

- Supports both forward and reverse conversions

- Customizable decimal precision for specific requirements

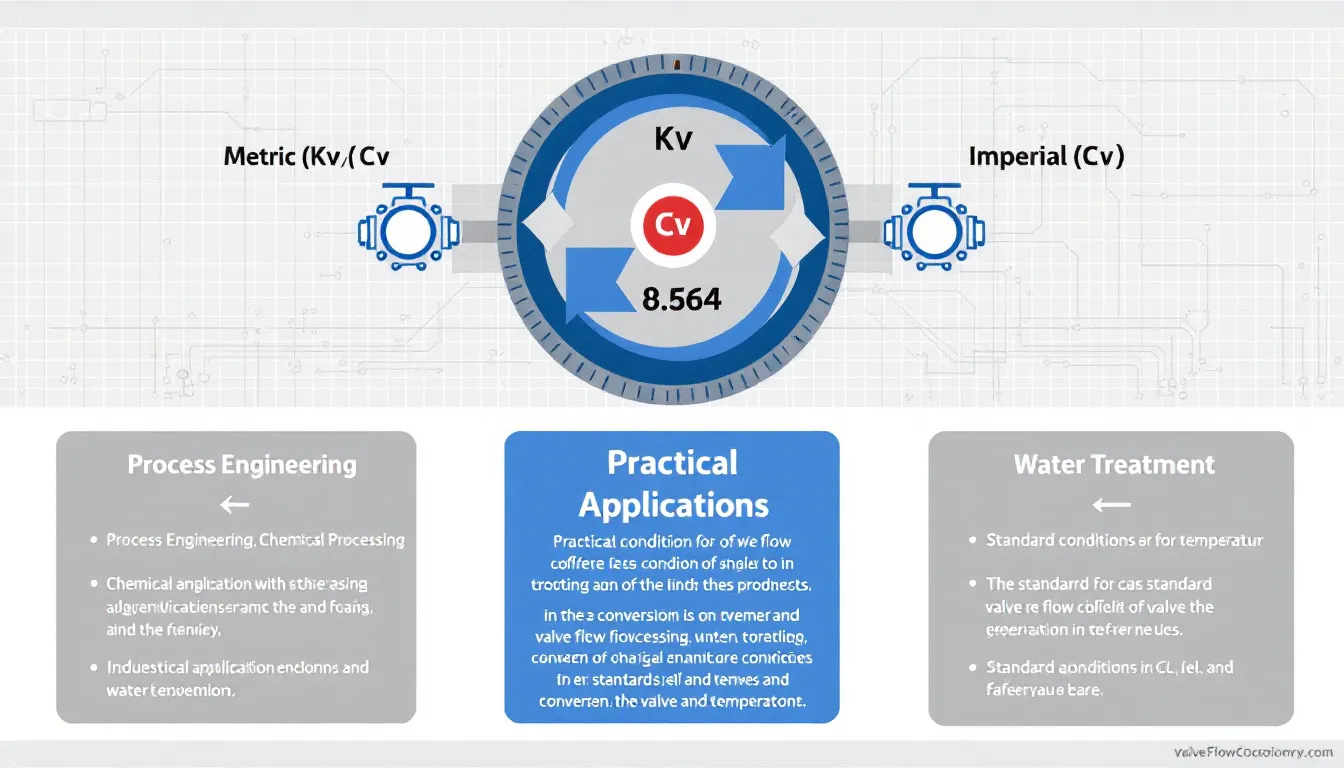

Practical Applications

Process Engineering

Process engineers frequently need to convert between Kv and Cv when:

- Selecting valves from international suppliers

- Converting specifications between metric and imperial systems

- Validating valve sizing calculations

- Preparing technical documentation

Example Calculations

Consider a process requiring a control valve with Cv = 75 GPM. To find the equivalent Kv:

- Select “Cv to Kv” conversion

- Enter “75”

- Result: Kv = 64.80 m³/h

Plant Maintenance

Maintenance engineers use this converter when:

- Replacing existing valves with alternatives

- Cross-referencing valve specifications

- Updating facility documentation

- Sourcing replacement parts

Industry Applications

Chemical Processing

Chemical plants often work with international standards and equipment specifications. Converting between Kv and Cv is crucial for:

- Equipment procurement

- Process design verification

- System optimization

- Compliance documentation

Water Treatment

Water treatment facilities utilize this converter for:

- Flow control system design

- Valve selection and sizing

- System upgrades and modifications

- Performance verification

Advanced Usage Tips

Temperature Considerations

While the converter assumes standard conditions, users should note that actual flow coefficients may vary with temperature. Standard conditions are:

- Kv: Water at 16°C

- Cv: Water at 60°F

Documentation Best Practices

When documenting conversions, always:

- Include both Kv and Cv values

- Specify the reference conditions

- Note the conversion direction used

- Document the decimal precision applied

Frequently Asked Questions

Why do we need both Kv and Cv values?

Different regions and industries use different measurement systems. Kv is common in metric countries and European standards, while Cv is prevalent in North America and other regions using imperial units.

How do these coefficients relate to valve sizing?

Flow coefficients help engineers select appropriately sized valves for specific applications by quantifying the valve’s flow capacity under standardized conditions.

Can I use these conversions for any type of valve?

Yes, the conversion factors apply to all valve types, including control valves, ball valves, butterfly valves, and globe valves.

Do I need to consider other factors when selecting valves?

While flow coefficients are crucial, valve selection should also consider factors such as pressure rating, material compatibility, and operating conditions.

How often should I verify valve coefficients?

It’s recommended to verify valve coefficients during initial design, system modifications, and when replacing equipment to ensure proper system performance.

What’s the significance of the decimal places setting?

The decimal places setting allows users to match the precision requirements of their specific application or documentation standards.

Can these conversions be used for gases?

While the converter’s values are based on water flow, the conversion factors remain the same for gas applications, though additional calculations may be needed for proper valve sizing.

Important Disclaimer

The calculations, results, and content provided by our tools are not guaranteed to be accurate, complete, or reliable. Users are responsible for verifying and interpreting the results. Our content and tools may contain errors, biases, or inconsistencies. We reserve the right to save inputs and outputs from our tools for the purposes of error debugging, bias identification, and performance improvement. External companies providing AI models used in our tools may also save and process data in accordance with their own policies. By using our tools, you consent to this data collection and processing. We reserve the right to limit the usage of our tools based on current usability factors. By using our tools, you acknowledge that you have read, understood, and agreed to this disclaimer. You accept the inherent risks and limitations associated with the use of our tools and services.